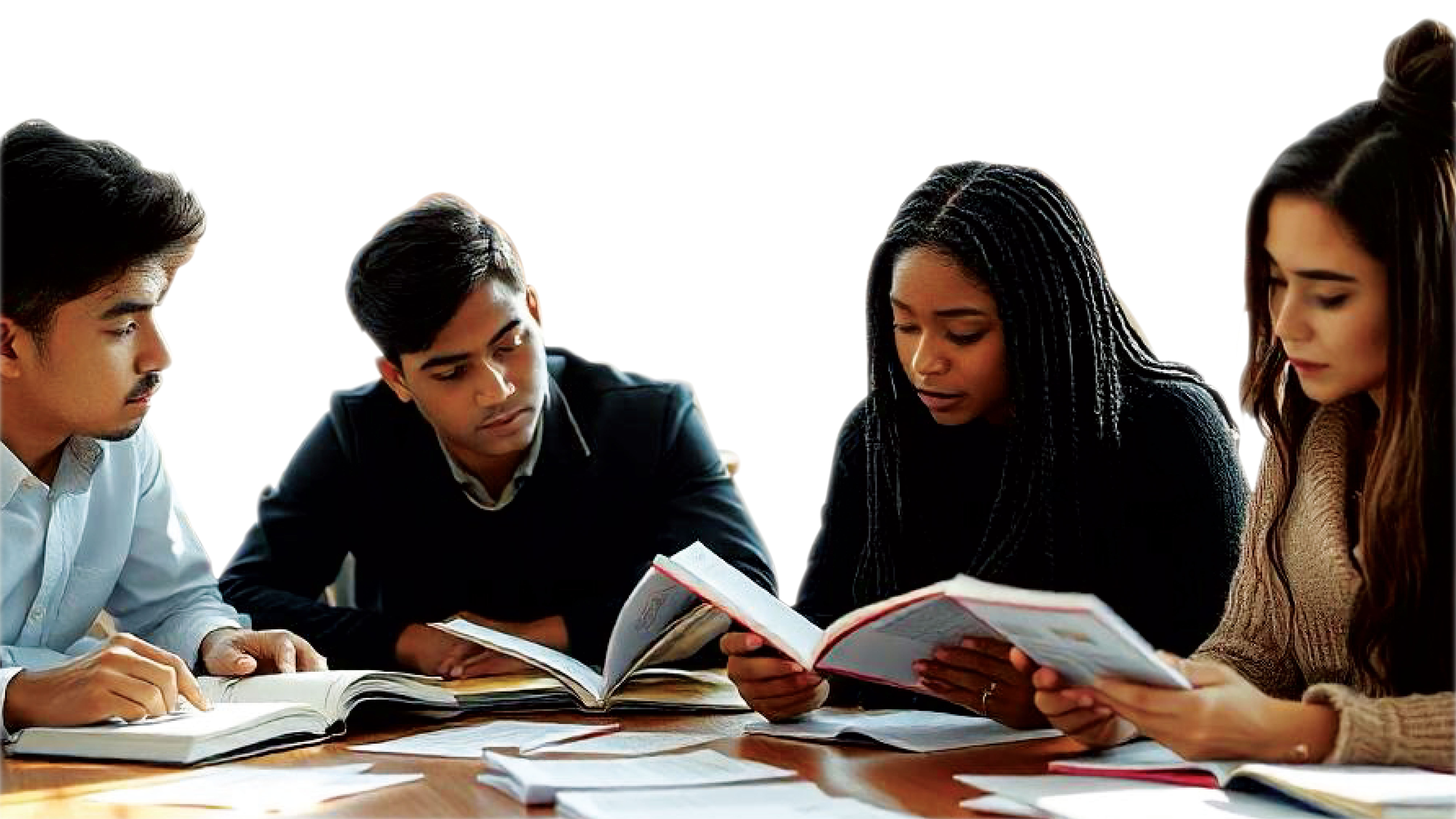

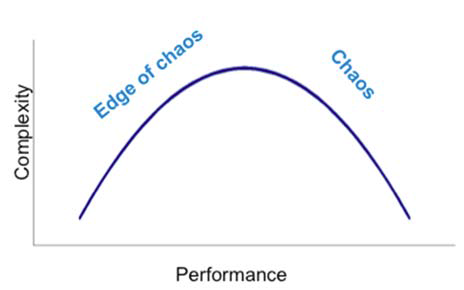

Operational complexity enhanced performance in Malaysia Electrical and Electronics (E&E) Manufacturing industry. The finding surprised a group of researchers from USM and UTM initially. However, when looking through the lenses of complexity science, an organization behaved based on complex adaptive system (CAS). An organization (consists of people like you and me) when faced with CHANGE would somehow adapt through self-learning, organize, experiment and exploration. ‘Edge of chaos’ (complexity) occurs when there is a change or disruption to the normal routine in operation. According to the CAS, performance is optimum at the ‘edge of chaos’. But, as complexity increases in tandem with performance, it will reach a threshold and turn ugly like an inverse U shape graph.

The survey-based study recorded a response rate of 17.8% from a sampling frame of 858 E & E manufacturing companies throughout Malaysia. Partial Least Square Structural Equation Modelling (PLS-SEM) technique was applied to analyze the data obtained from the cross-sectional study. The findings showed that complexity operationalized by complicatedness and uncertainty has a significant positive relationship with operational performance.

The findings imply that managers should take caution and be aware of impending chaotic stage especially when performance seems to be improving with the increase in operation complexity. Managers must not be intimidated with complex operations and continue to learn how to surf at the ‘edge of chaos’ where performance is optimum.

The study suggested 2 approaches in managing complexity:

- Complexity-absorption approach can be applied at organizational level to facilitate learning and stimulate innovation.

- Complexity-reduction approach can be applied at process level to reduce process variation and enhance control

The findings imply that managers should take caution and be aware of impending chaotic stage especially when performance seems to be improving with the increase in operation complexity. Managers must not be intimidated with complex operations and continue to learn how to surf at the ‘edge of chaos’ where performance is optimum.

Original article

Nasuha Lee Abdullah(USM), Khairur Rijal Jamaludin(UTM), Hayati Habibah Abdul Talib(UTM), 2015. Operational Complexity Impact On Performance Of Electrical And Electronics Industry In Malaysia, ARPN Journal of Engineering and Applied Sciences Vol 10 (15) pp.6593-6601 [SCOPUS indexed journal]