Wouldn’t it be great if food plastic packaging able to change colour to warn us about the freshness of the food? How about a smart protective equipment that can change colour as indicator to over exposure to bacteria and viruses that are commonly present in the hospital?

A breakthrough invention by Dr Ku Marsilla Ku Ishak and her research team from School of Materials & Mineral Resources Engineering USM has successfully created a smart plastic that can change colour over exposure to different environment.

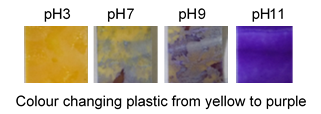

Halochromic plastics are designed to change colour at a specific pH, giving a visual indication of the pH changes. These halochromic behaviour autonomously activates due to chemical changes among components added into the polymer. The colour changes are REVERSIBLE and stable at various pH conditions. Once exposed to the base condition, the plastic turns from yellow to blue colour within a minute and able to reverse its reaction when the pH changes back to acidic condition.

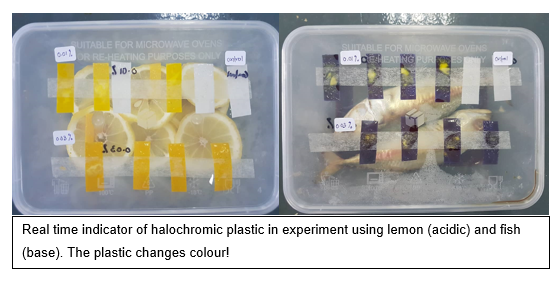

In general, the freshness and quality of our daily food products can be observed through visual inspection, odour, and appearance. The food producer usually provides expiry date as an indicator for food freshness. However, when the container is opened the food freshness might vary according to the exposed environment. Furthermore, there is no available real time indicator for poultry and seafood products.

The invented smart plastic developed in this work can trigger the release of volatile amines which predominantly produced by the increase of bacteria activities during deterioration of food over time. The real time indicator would benefit the consumer to decide the quality of the food.

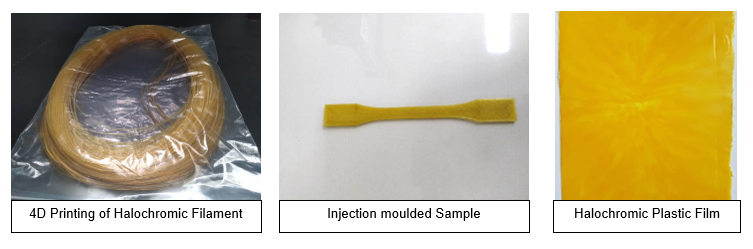

Interestingly, the material sensitivity and colour changes are consistent over repeated usage as long as the service temperature does not exceed the melting point of the polymer. At present, the team has fabricated halochromic plastics using various commercial grade polymers such as polylactic acid (PLA), poly butylene terephthalates (PBAT), high density polyethylene (HDPE), polypropylene (PP), and low density polyethylene (PE).

The halochromic raw materials can be fabricated into plastic film, injection moulded products and more recently the team has successfully used the materials in 4D Printing which offers huge opportunities to fabricate customized products for specific applications. The team is now looking into exploring more types of polymer and composites that have the potential to be converted into smart halochromic materials.

Yes, plastic can change colour! And we put high hope that this invention can penetrate the market as soon as possible. Please click the following link for the DEMO video. https://www.youtube.com/watch?v=WnA6KKI1t5M&t=5s

For more information, please email me at This email address is being protected from spambots. You need JavaScript enabled to view it.. The author would like to acknowledge her team for great their effort and continuous support; Jia Yam, Zulkarnain, Ooi Pin Chou, Siti Amirah, Siti Asiah and Syira. Thank you.