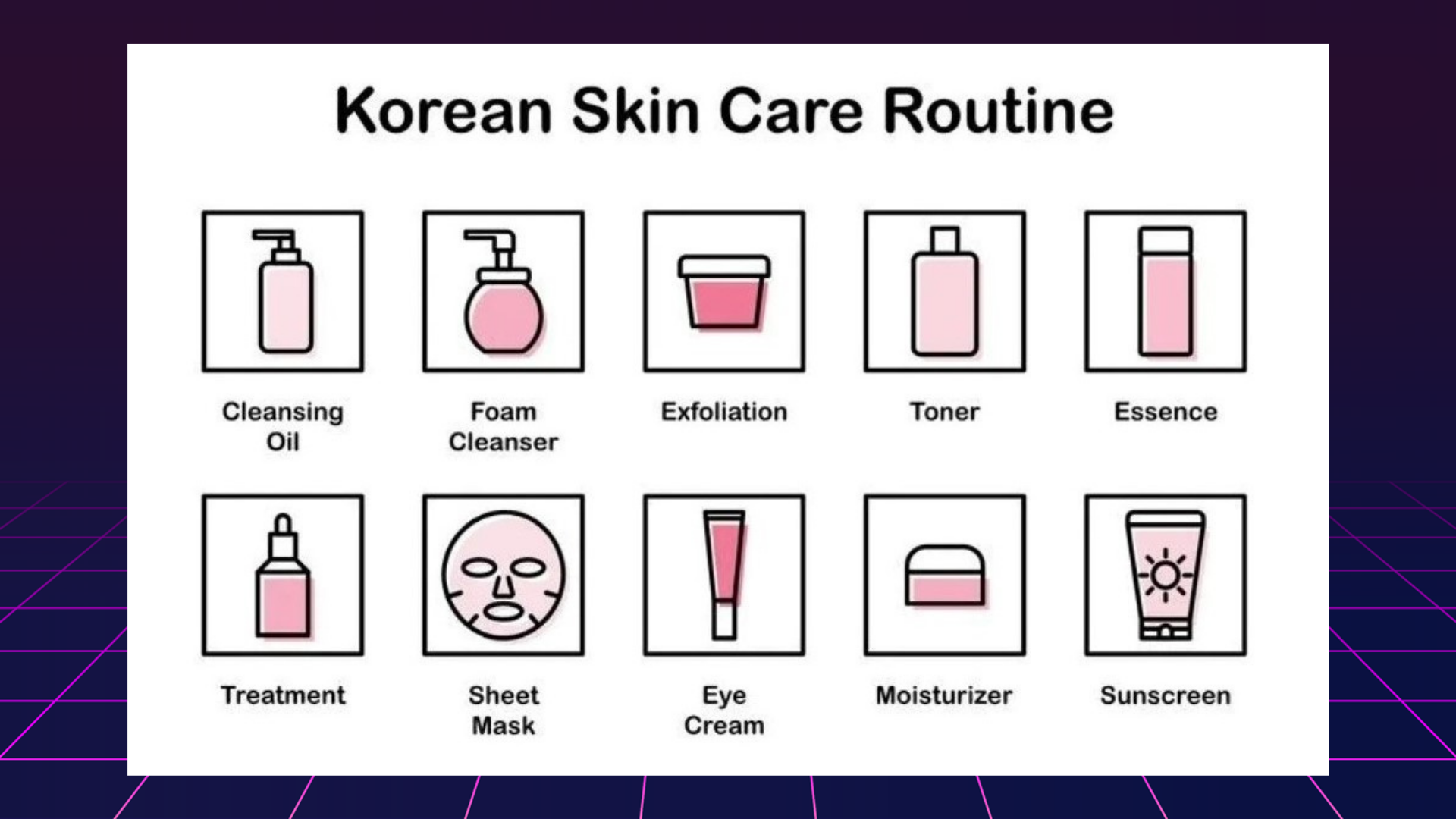

A SIMPLE Kanban (Japanese for signboard) board saved the day for employees of an IT department at a multinational manufacturing company in Penang.

Kanban is actively used in the manufacturing industry as a scheduling system that uses the “pull concept”.

The research conducted by USM researchers found that incorporating the Kanban concept greatly improves the effectiveness of Scrum - a framework for handling complex software projects that are currently being adopted by many organisations worldwide. The employees tasked with deploying software projects are still struggling to adapt to Scrum even though it has been implemented a year ago at their company.

Lack of visibility of each other’s task, difficulty in handling task priorities, lack of work synchronisation, too many tasks at the middle of sprints are among the challenges they faced.

In the literature, Scrum is reported to deliver many benefits such as higher productivity, reduced time to market, increased job satisfaction, lower bug rates, quicker adaptation to rapidly changing business needs.

However, the findings by USM researchers imply that the employees were somewhat made to implement Scrum and have yet to reap the benefits from it. Lack of visibility of each other’s task, difficulty in handling task priorities, lack of work synchronisation, too many tasks at the middle of sprints are among the challenges they faced.

The USM researchers found that updating and displaying the team’s tasks on a Kanban board and using the “pull concept” in Kanban greatly improves the implementation of Scrum. The findings reaffirmed one size does not fit all.