Have you ever read through your chocolate bar’s ingredients and wondered how each of the components mix and the chocolate appear in one solid form? Or while eating the bread, how does it become a slice of bread from multiple components in the ingredient lists?

Well, thanks to emulsifiers which successfully 'bind' all the ingredients and appear as it is supposed to be. An emulsifier (‘pengemulsi’) is an agent to mix two or more immiscible fluids and form a stable mixture. An example of immiscible fluid is water and oil, in which these two will form a separate layer without emulsifiers. Emulsifiers are usually used in a small amount yet are so beneficial in combining complex food ingredients and improving the texture of food products.

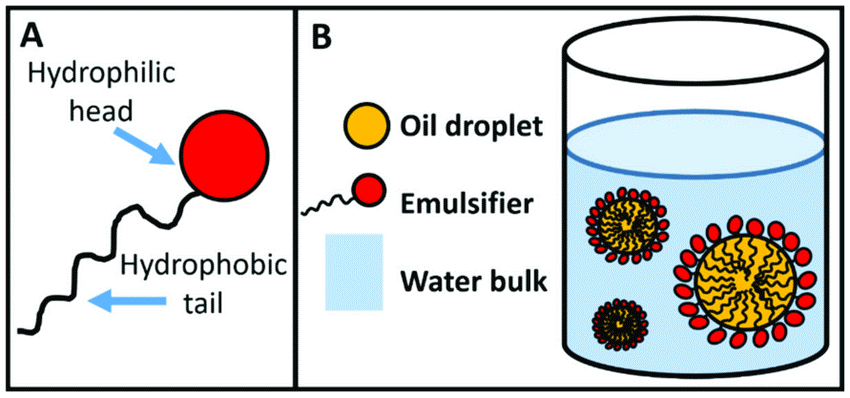

Emulsifier molecules come with two different ends which are hydrophilic (loves water) and hydrophobic ends (hates water). In a water and oil mixture, the hydrophilic end will bond with water and the hydrophobic end will bond with fat. With the addition of an emulsifier in the water and oil mixture, the mixture becomes stable and does not separate into different layers. There are two types of emulsion which are oil-in-water emulsion and water-in-oil emulsion. It is depending on the composition of oil and water in the mixture.

Historically, beeswax is the oldest known emulsifier which used in making skin lotion by the Greek physician Galen (131-201 AD). The egg yolk also used widely in the early 1900s in the making of mayonnaise, makes it the first emulsifier used in food application. It is known that the phospholipid lecithin content in egg yolk has helped in dispersing liquid oil in the aqueous phase. It was not long after, the discovery of the first mono and diglyceride as an emulsifier on an industrial scale promotes the commercial application of emulsifiers. The synthetic emulsifier emerged around mid of 20th century, boosted the production of food worldwide. Food emulsifiers are manufactured by esterification of edible fatty acids with polyols such as glycerol, propylene glycol, etc. The fatty acids are commonly taken from animal or vegetable sources. The produced emulsifier will then be distributed to food manufacturers for their daily production.

Now let's look to the science behind the emulsification process. The mixing of oil and water with an emulsifier is spontaneous self-organization of hydrophilic groups in contact with water and the hydrophobic tails are in contact with oil. Emulsifiers reduce the interfacial tension between the water phase and oil phase, hence resulting in easy mixing of oil and water, this example is not limited to oil and water only, but also represents phases of various immiscible substances such as carbohydrates, proteins, and fats on interfaces.

So, how much emulsion is enough for the oil and water mixture? There is one term, HLB (hydrophilic-lipophilic balance) value which is unique for every mixture. The HLB is in the range from 0 to 30 which corresponds to the lipophilicity (having an affinity towards fat/lipid). The matching value of the emulsifier and its application helps to develop stable formulations. For example, the required HLB for oil is the HLB value of the emulsifier that will provide the lowest interfacial tension between the oil phase and water phase. Hence, the lowest interfacial tension equals the lowest amount of emulsifier. The procedure for choosing appropriate matching for this HLB value could be much more complicated when we have multiple ingredients.

Emulsifiers in food production

In food production, the addition of emulsifiers has done more than just stabilize the ingredients. In bread production, an emulsifier was added to enhance the volume and dough stability, improve shelf life. Another example is margarine/butter spread, in which emulsifier helps with promoting stable emulsion, have smooth spreadability, and improve the flavor release when consumed. While in ice cream production, the addition of an emulsifier helps improve the smooth texture of ice cream. Without an emulsifier, the fat globules will agglomerate and appear as undeformed textures. You also could find emulsifiers in other products such as mayonnaise, margarine, salad dressings, chocolate, peanut butter, and in your favorite cookies.

Let me introduce you to one of the common emulsifiers, polyglycerol polyricinoleate (PGPR). It is made from glycerol and fatty acids, which serve as an additive in chocolate production. When you read Hershey’s chocolate ingredient, you will notice the code for PGPR which is E-476. The PGPR appears as a high viscous liquid and yellowish. PGPR is added about 0.1% in the production batch of chocolate to bind the ingredients and hold them together.

Another common emulsifier is lecithin, which originated from soy and egg. It is used as aerating agent, viscosity modifier, and dispersant. Lecithin as an emulsifier helps to reduce the surface tension between two liquids and allows them to mix and form a stable mixture. That is the reason for having egg in almost all cake recipes. Other than the type mentioned above, there were other types of an emulsifier such as polyglycerols esters, propylene glycol esters, stearoyl lactylates, and sorbitol esters. The choice of emulsifier is depending on the difference in oil/fat or water dominant situation.

How do we know the emulsifier are safe for consumption?

Commonly the emulsifier is used in small amounts and then it should be recognized as safe by the U.S Food and Drug Administration (FDA). Nowadays, more and more people become conscious about what they eat. Hence there is a movement to replace processed emulsifiers with natural emulsifiers as it deems healthier alternatives. However, as FDA approved current processed/synthetic emulsifier, the consumer has nothing to worry about. FDA has been strict with food standards and safety. Manufacturer also need to be transparent and accountable for the ingredients that been put in the food production. Most importantly, on our side, do not eat excessively and enjoy your food moderately.

The current production of global food emulsifiers has estimated around 400,000 metric tonnes per year and is expected to increase its demands in the future. The manufacturer needs to choose suitable emulsifiers to maintain a uniform structure and prevent the separation of essential ingredients in food products. Emulsifying isn’t just useful for getting two unlike substances to hold together—when we take advantage of emulsification in the kitchen, we can create foods with properties unique from their starting ingredients. Consistent texture and flavor of the foods keep customers satisfied, while good stability and longer shelf life means less waste will be generated.

The author is a senior lecturer from School of Chemical Engineering, USM, and is currently attached at Danisco Malaysia Sdn Bhd. Danisco manufacture various kind of emulsifier for food application.

Further reading:

EMULSIFIERS | Uses in Processed Foods. T. Kinyanjui, S. Mahungu, in Encyclopedia of Food Sciences and Nutrition (Second Edition), 2003.

Manley, D. (2011). Emulsifiers (surfactants) and antioxidants as biscuit ingredients. In Manley's Technology of Biscuits, Crackers, and Cookies (pp. 181-190). Woodhead Publishing.